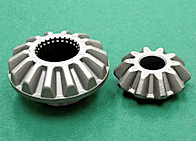

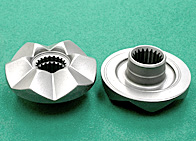

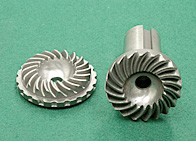

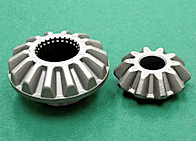

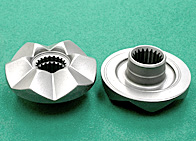

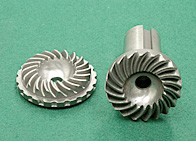

Our Product

Our company offers various gears that meets increasing demand for high strength, high quality, and low cost of differential mechanism, to respond to the trend of higher performance and power output of automobiles Various types of gears and parts, including bevel gear, differential gear, transmission parts, clutch, sprocket, die forgings, spiral gear, etc. are produced by hot forging. Their characteristics are:

1) Product strength is higher than Tooth cutting and cold forging by 20% or more.

2) More flexibility for detailed profiles or complex parts than cold forging.

3) Wider range of materials (high strength material, low cost material) enable gears of high quality with lower cost.

For more details for manufacturing process, product profile, material, quantity, or other enquiries, click here and send the message after filling out the form.

For more details for manufacturing process, product profile, material, quantity, or other enquiries, click here and send the message after filling out the form.

Range of Production

| |

Range |

| Tooth Outside Diameter |

Dia. 40mm∼280mm |

| Module (Diametral Pitch) |

Min. 3 (8 Max.) |

| Shaft Length |

200mm Max. (at 70mmDia. Max.) |

| Shaft Diameter |

Dia.22mm∼100mm |

| Tooth Surface Roughness |

3.2∼9.0μmRa

(Depend on Gear Size) |

| Weight of Product |

∼15kg (As Finished)

∼20kg (As Forged) |

*Above data is only guidance. Actual range is depend on the gear design.

![]() For more details for manufacturing process, product profile, material, quantity, or other enquiries, click here and send the message after filling out the form.

For more details for manufacturing process, product profile, material, quantity, or other enquiries, click here and send the message after filling out the form.